Ingenuity at Work: Bucknell Engineers Solve Professional Design Problems

March 23, 2023

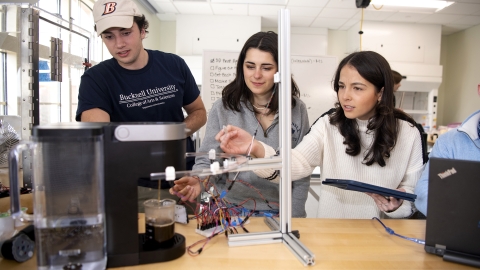

Jack Fiala '23, Haley Scopelliti '23 and Maddie Sanders '23 are part of an interdisciplinary team of engineers helping Keurig Dr Pepper innovate coffee-making. Photo by Emily Paine, Communications

When it comes to creating new equipment to advance his work in materials science, Brian Picarillo '18 has the utmost confidence in his collaborators.

Picarillo is overseeing a team of Bucknell College of Engineering students tasked with designing a specialty furnace for Corning Incorporated's Advanced Optics division, which produces precision glass for use in aerospace, defense and health care.

"I think this project is one of the most important things Corning is doing right now," says Picarillo, a thermal equipment design engineer. "When the students hand off their deliverables to us at the end of the semester, we'll be able to immediately implement their design into our furnace and start increasing our production. Bucknell is providing us with great value."

Putting such a consequential project into students' hands requires a tremendous amount of trust. But Picarillo and his Corning colleagues know what Bucknell engineers are capable of.

Back in 2018, Picarillo was a mechanical engineering major presenting his own senior design project to his client, Dan Hawtof '88, an innovation leader in Corning's research and development division. Things did not go according to plan. "Everything that could've gone wrong went wrong," Picarillo says. "There were leaks and sparks. People left the room."

But in that challenging moment rose an opportunity. Instead of panicking or hesitating, Picarillo rushed in. "I ran over and started triaging the situation," he says. "I plugged things in, closed up the leaks and focused on problem-solving."

Picarillo's strong technical skills, honed over three years of study in Bucknell's classrooms and labs, had been evident along the way. But what he demonstrated in this moment — the ability to perform under pressure, be creative, lead a team, take accountability — were differentiators. And it ultimately led Picarillo to receive a job offer from the renowned glass and ceramics manufacturer.

Now, nearly five years later, Picarillo is leading the Bucknell-Corning partnership, providing guidance, mentorship — and reassurance that sometimes things need to go wrong before they can go right — to the next generation of engineers.

Corning is just one of more than 20 companies participating in Bucknell's College of Engineering senior design course this academic year. Seniors across the college's eight engineering majors are collaborating on projects that can make real-world impacts for a range of companies and organizations, including Keurig Dr Pepper (KDP), the regional Geisinger Health System and local food and beverage manufacturers.

The program is a win-win: Engineering students spend their senior year applying skills and knowledge they've accumulated in Bucknell's classrooms while receiving ongoing feedback from an industry professional. Corporate partners benefit from tapping a pool of high-performing students who have fresh perspectives and access to expert faculty and state-of-the-art resources, all of which can propel their projects forward.

"The hands-on opportunities Bucknell engineers receive by working with our senior design partners is extremely beneficial," says College of Engineering Dean Brad Putman. "I continue to be impressed by the innovation of the solutions and ideas the students develop and share. They get to develop teamwork, communication and leadership skills while having professional interactions with their mentors and taking that next step toward their successful post-Bucknell careers."

Smells Like Success

Coffee enthusiasts know just a whiff of freshly brewed coffee can invigorate the senses. It's not just your imagination: Research shows the fragrance of coffee can boost mood and alertness. Beverage company KDP recognized the opportunity to enhance that experience and asked Bucknell to investigate.

Jack Fiala '23, James Owens '23, Maddie Sanders '23 and Haley Scopelliti '23 make up an interdisciplinary engineering team tasked with helping to boost the aroma of French vanilla or chocolate hazelnut as it drips from K-Cup pod to mug. After an initial research phase, the team, which is made of two mechanical engineers, a chemical engineer and an electrical engineer, identified exit steam as the lynchpin to their operation.

As they began designing prototypes, questions surfaced: Can a fan enhance steam flow without negatively affecting the coffee stream? Should the steam be released through holes or slots — and how big should they be? What impact does the humidity of the room have?

All these factors need to be considered, and their designs need to be tested and tested, again and again.

"Working with external clients helps students develop increased confidence during senior design," says Professor Ben Wheatley, mechanical engineering (center), who oversees the interdisciplinary teams working with KDP and Corning. Photo by Emily Paine, Communications

"In class, you are usually solving an idealized textbook problem that is pretty straightforward and generally has a simple solution," says Sanders, a mechanical engineering major. "With this project, we develop plans we think will work, but then things go wrong. Or we find success once but struggle to replicate it. We need to manage all of that while continuing to move the project forward."

Contending with those challenges to deliver for a client requires diligence. It also builds confidence. "We are all so invested in this project," says Scopelliti, a chemical engineering major. "When our plans come together, it's exciting. When we meet with our client, and she is like, 'Wow, that works really well,' it's really rewarding."

KDP sees the benefit as well. "The well-refined course structure walks students through the scope of the design project, allowing the mentors and the team to achieve each milestone as a team and according to a dedicated timeline," says Christie Bielmeier, a principal mechanical engineer for appliance and pod development at KDP. "For the aromatics project, we worked with the team to improve a key feature of the coffee experience by creating concepts that enhance aroma. The design-build-test methodology of the project produced incredible feedback that will not only serve not only these talented students but also help us consider future innovation."

Practical and Tactical

Professor Keith Buffinton, mechanical engineering, who has taught at Bucknell since 1987, has witnessed the evolution of the program. When it was conceived in the 1980s, it was considered innovative; such hands-on capstone projects were not commonly offered. Initially the projects were internal — generated by faculty and contained to campus. In the 1990s, faculty realized forging external relationships could provide students broader experiences and exposure to industry professionals.

Since then, more than 3,000 of Bucknell's senior engineering students have worked with more than 300 companies and institutions on more than 700 projects. This year, more than 80% of the projects are sponsored by external organizations, many of whom are repeat collaborators. "The companies who re-engage with us are certainly interested in our students' technical skills," Buffinton says. "But I think what sets our program apart is that we help to define the problem and can reassess things. We have conversations about what we've been asked to do and discuss whether that is really worthwhile and if it adds value. That inevitably produces better results for the client."

In addition to established partnerships, new opportunities are always emerging — especially as graduates enter the workforce. A group of mechanical engineers are helping restaurateur Kevin Takarada '02 automate his sushi-making process. Meanwhile, a team of computer engineers are working with Kellen Haile '18 on an artificial intelligence project for global technology company TE Connectivity.

Each team's ultimate goal? To deliver a well-conceived prototype that can become an actual product or initiative that ends up in the marketplace. And it happens. Bucknell-engineered designs have resulted in several patents over the years. Buffinton says one such success story is a syringe developed by a Bucknell team that allows emergency responders to administer a drug to patients in volatile environments like helicopters.

As the end of the semester approaches, Picarillo has confidence in his team (Sophie Bae '23, mechanical engineering; Evan Gander '23, mechanical engineering; Jordan Sukin '23, biomedical engineering; and Ziheng Zeng '23, chemical engineering) and high expectations for their final presentation. If there's an unanticipated spark, leak or hiccup, Picarillo won't flinch. He knows Corning will gain valuable deliverables and insights, and the students will have succeeded by embracing whatever comes their way.