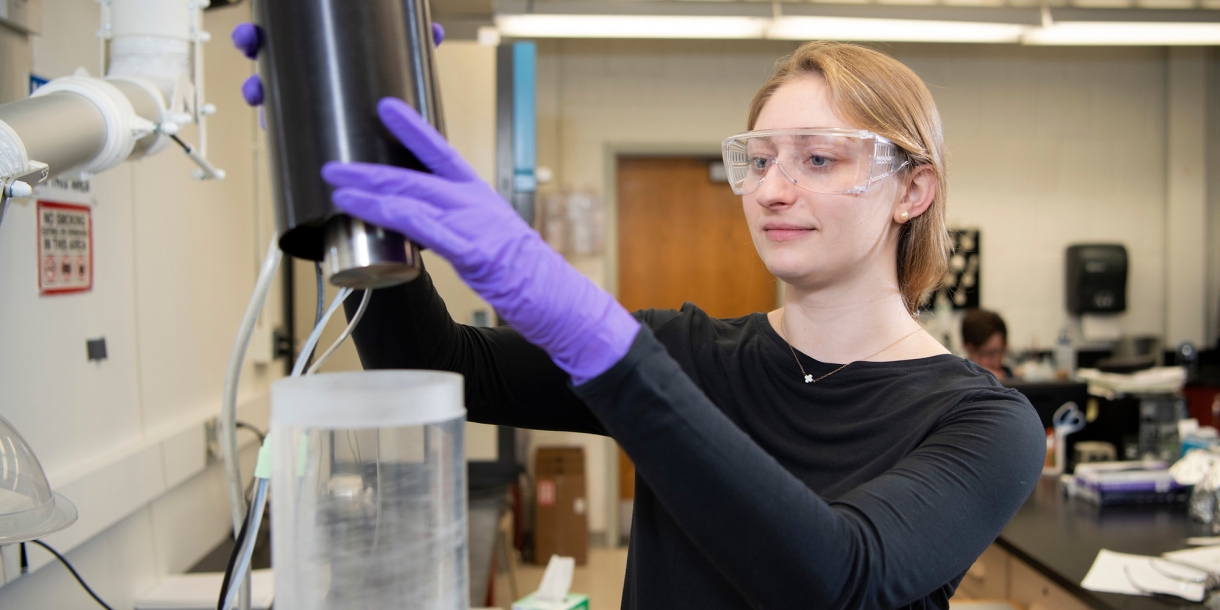

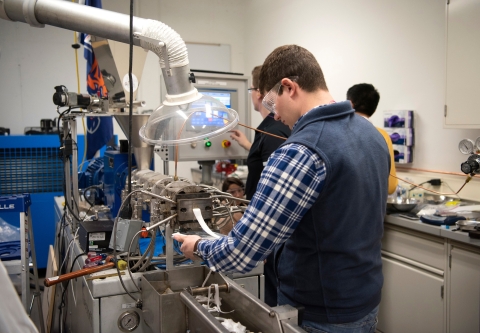

Labs & Learning Spaces

Chemical Engineering

The hands-on experience students gain in our state-of-the-art labs is one reason Bucknell's College of Engineering is ranked among the best undergraduate schools for chemical engineering. We put industrial-grade research and analysis tools in the undergraduates from their first year on campus, teaching them skills they'll use in their first jobs in the field and throughout their careers.

Analytical Laboratory

The Analytical Laboratory provides physical and chemical analysis and characterization tools supporting both lab courses and student and faculty research activities. Research tools include infrared and ultraviolet spectroscopy, gas and liquid chromatography, thermomechanical and differential thermal analysis, and light and atomic force microscopy.

Biochemical/biomedical Laboratory

The biochemical/biomedical laboratory includes facilities for research involving microorganisms, including study of organism attachment, detachment and movement. Equipment includes an internal reflection aqueous fluorescence microscope, which can also be used as a regular light microscope. Equipped with a CCD camera and computer image capture, it is capable of imaging cells and measuring the distance between adhered cells and the surface with nanometer precision. Other equipment includes facilities for cellular cultivation, filtration, zeta potential measurement, biofluid mechanics visualization, analysis of experimental multiphase flows and biomedical signal monitoring. Undergraduate and graduate students use this equipment to do novel research in bacterial adhesion and contamination.

Bioprocess Laboratory

Bioprocess engineering involves harnessing biological materials or mechanisms to produce chemical products. The bioprocess lab contains facilities and materials for batch cultivation of microorganisms at three scales: shake flask, 2-L fermenter and 10-gallon non-stirred fermenter. A state-of-the-art 2-L bioreactor allows computer control and measurement of pH, dissolved oxygen, temperature and aeration. Students use this equipment in senior design and elective courses to study industrial fermentation.

Fluid Flow Laboratory

The Fluid Flow Laboratory teaches students to use industry-standard equipment for characterizing important properties of fluids, such as viscosity and surface tension. The equipment in this lab gives students a hands-on introduction to a wide range of practical experiments in areas such as fluidized beds, frictional losses in piping systems and unsteady flow phenomena, all of which are critical aspects for the successful practice of chemical engineering and design of chemical processes.

Heat and Mass Transfer Laboratory

The Heat and Mass Transfer Laboratory offers equipment to help students design and analyze heating and cooling operations and separation processes, and conduct experiments concerning how quickly energy or material substances move from one place to another. Experiments conducted here explore of fluidized-bed heat transfer, boiling-film heat transfer, countercurrent heat exchange, thermal conductivity, home heating system design and radiation, as well as membrane separations and liquid-liquid extraction.

Kinetics Laboratory

The heart of many chemical engineering operations is the chemical reactor. This laboratory supports team-based and student-defined projects investigating reaction engineering problems in areas of interest within the chemical industry. The lab offers experimental space and equipment for several reactor and reaction types, including batch, continuous, catalytic, contaminant cleanup and fermentation. These are supported by modern analytical tools such as ion, gas and liquid chromatography, light and ultraviolet spectroscopy, and inline sensors that allow reaction parameters to be monitored and analyzed by computer.

Materials Science Laboratory

Studying the properties of engineering materials, and the relationships between these properties and atomic structure, allow engineers to logically select materials for certain applications, and to modify or design new materials to meet specified needs. The Materials Science Laboratory provides opportunities for analysis of metals, plastics, ceramics and composites. Equipment includes hardness and impact testers, high-temperature furnaces, computer-controlled universal testing machines, optical and scanning electron microscopes with digital imaging capabilities, electrical and thermal analysis stations, and materials processing equipment.

Polymers Laboratory

Polymers are very large molecules we encounter daily in materials such as plastics, rubbers, adhesives and coatings. The study of making polymers and controlling their properties continues to be at the forefront of many emerging technologies such as microelectronics, composites, and biomedical engineering. The Polymers Laboratory offers equipment and experiments that cover a wide range of topics, from synthesis of large molecules to polymer characterization to parts fabrication, such as extrusion and injection molding.

Process Control Laboratory

Automated process control is essential for the effective and efficient operation of industrial chemical processes. The Process Control Laboratory teaches students about feedback control of various process operations, including surge tanks and heaters, as well as about the dynamics of process components such as temperature sensors and pneumatic valves.

Unit Operations Laboratory

The Unit Operations Laboratory allows students to gain hands-on experience while studying both the fundamental principles and practical applications of chemical engineering. The lab includes plant scale equipment that represents unit operations found in industrial settings. This equipment includes distillation columns, counter-current heat exchangers, ion exchange units, gas absorption and liquid-liquid extraction columns, membrane separators, drying units (including a spray dryer), plate and frame filter press, and an analytical lab and process control room. This lab is specifically designed to introduce students to larger scale industrial processes commonly encountered by chemical engineers. Students work in teams to apply principles learned in the classroom to solve practical engineering problems.